Industrial Motor Repair

Dual Motor Labs for Testing and Repair

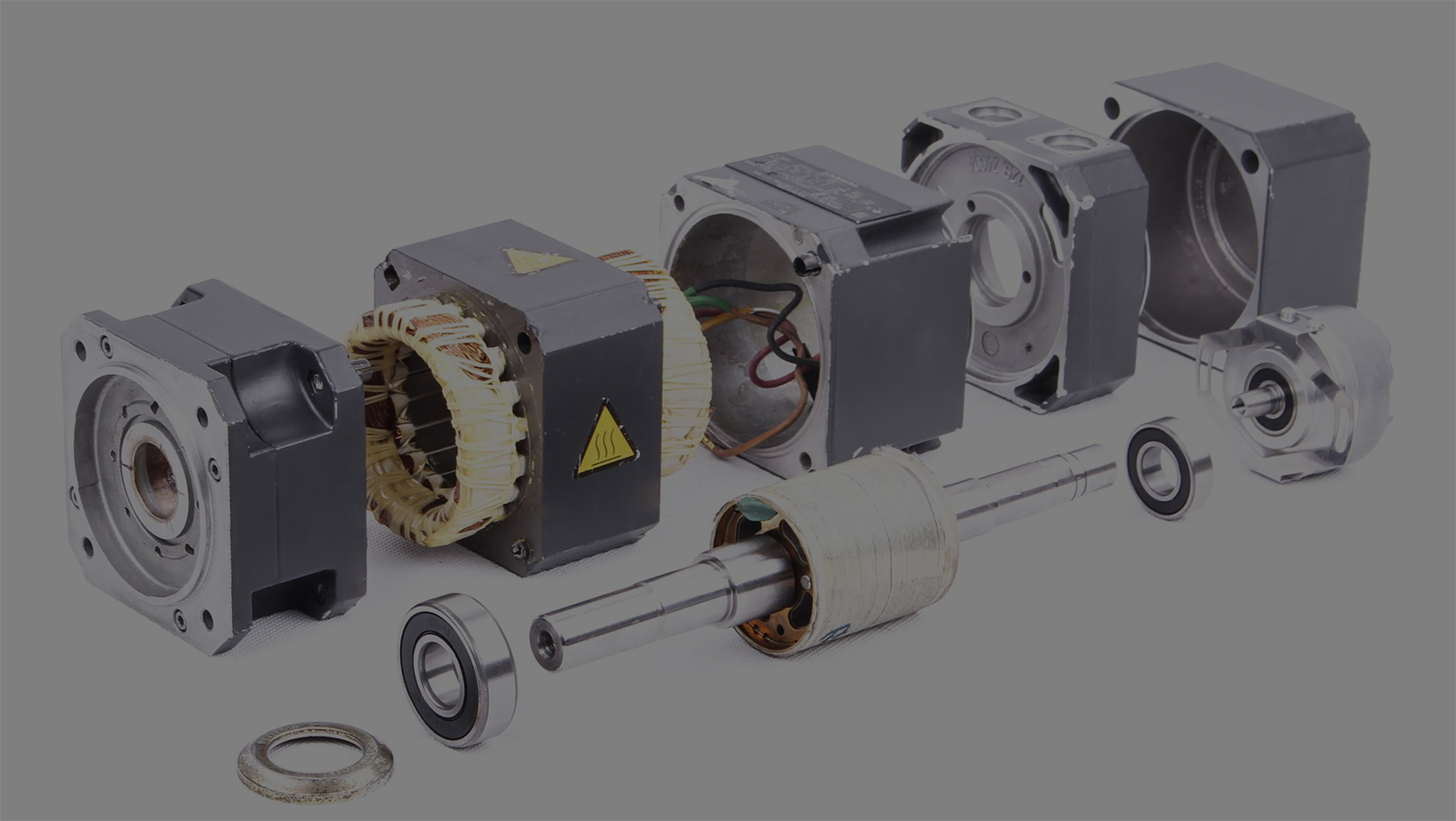

Universal Servo gives you the ability to send all your industrial motor repairs to one, single facility. USG has the equipment to perform all electrical and mechanical tests on any AC, DC, Spindle, and Servo motors. With our custom simulation and specialized equipment, we can test and align all types of feedback used in the industry today. We provide an UPFRONT failure report with each evaluation, free of charge. With the advancement of technology, equipment is becoming obsolete faster than ever. Looking to repair or replace an obsolete item? We offer Baldor servo motor repair, Siemens motor repair, Fanuc motor repair, Rexroth Indramat servo motor repair, and more so call us today!

Testing/Repair Procedures

Each unit is tested to ensure the motor does not need a rewind. Next, the feedback is checked to ensure it is functioning properly and we retrieve the lock up position. This allows us to properly realign the feedback after the repair is complete. If the motor is equipped with a brake, USG checks to ensure the brake meets or exceeds the minimum NM of torque specified by the manufacturer. The motor is then completely disassembled, inspected for wear, and to see if machine work is needed on parts such as the bearing journal, brake, or keyway. We even routinely machine and repair broken shafts on all types of motors. Pictures are provided showing the results of the surge tests and the Hi-pot test as well as any damage and/or contamination throughout the motor. This reporting shows you what is causing the failures and builds trust in the quality of repair you are getting each time you use Universal Servo. Contact us for an RMA to send in your motors!

Looking for a discontinued or obsolete part?

We specialize in helping you find the best solution.

Brands We Repair

VIEW ABB PART NUMBERS

VIEW ARBURG PART NUMBERS

VIEW FANUC PART NUMBERS

VIEW KUKA PART NUMBERS

VIEW MITSUBISHI PART NUMBERS