One of the questions I am often asked is “What should the oil temperature in my hydraulic system be?”. The short answer to this question is 100°F to 120°F. When most people think about the effects of oil temperature in a hydraulic system, the immediate thought is on the subject of excessive oil temperature, and the general recommendation is not to exceed approximately 140°F. However, cold oil temperatures can also adversely affect the operation of hydraulic systems. This can be especially problematic with mobile applications where the equipment must be operated and stored outside during the winter months, but low oil temperature can also affect the operation of hydraulic equipment operating within an industrial environment.

Low oil temperature can affect the hydraulic system in a couple of ways.

1. Elastomeric seals are found in hydraulic systems of all types. There are many types of seal and hose elastomers (compounds) available, and each compound is designed for specific temperature ranges. These compounds are sensitive to temperature extremes, and cold temperatures can cause the compound to become brittle. If this happens, the seal or hose can be damaged. In addition, cold temperatures can adversely affect the sealing properties of the elastomer.

2. Cold temperatures will affect the viscosity (thickness) of the oil. Viscosity is a measurement of a fluid’s resistance to flow. Simply put, the higher the viscosity of the oil, the more resistant it is to flow. Low temperatures will increase the viscosity of the oil, which can cause numerous problems, including cavitation in pumps and reduced lubrication. In addition, the increased viscosity results in reduced flow through flow controls (assuming they are not temperature compensated). This will result in reduced actuator speed and sluggish performance until the oil reaches a normal operating temperature.

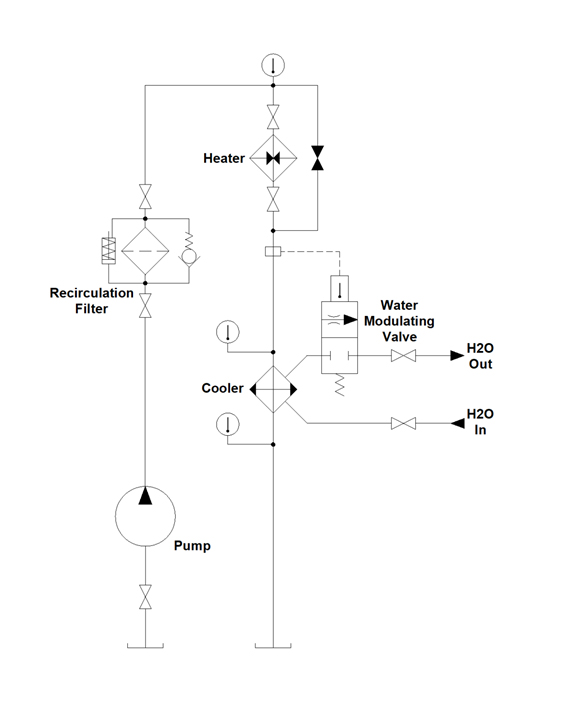

Obviously, the oil temperature will be maintained while the system is in operation, but what about extended periods of downtime when the system is not operating? We need a way to keep the oil temperature at a level which will allow for normal operation when the equipment is placed back into service. Although there are a few methods which can be used for this purpose, one of the most effective methods is to use an electric heater to maintain the oil temperature. Most industrial systems utilize some type of recirculation system for filtration and cooling of the oil. A heater can easily be installed in this recirculation loop. The setting of the heater’s thermostat must of course be set at a temperature sufficiently lower than the setting of the cooler to prevent the heater and cooler from “fighting” each other. Below is a sample circuit utilizing one of these heaters:

Since low oil temperature can adversely affect the operation of a hydraulic system, the operating environment must be considered. The seals used and the oil viscosity must be suitable for the specific operating conditions, and some method should be used to maintain the oil temperature at a normal level. Failure to do so can lead to reduced system performance and possible damage to the components in the system.

Please visit our services page to see the brands of industrial automation equipment we repair. If you have a specific part that you need to be repaired, you can search our parts database to see if we offer a repair. If you don’t see your brand or part listed, just give us a call at 678-947-1150 – chances are we can repair it!