Excessive heat can affect a hydraulic system in many ways. Generally, oil temperatures in excess of 140°F (60°C) will cause the oil to rapidly degrade. Other effects include accelerated wear of system components and damage to bearings and seals. Therefore, high oil temperature is a major concern. A properly sized and located heat exchanger in a hydraulic system can save time, money, and repair headaches. Most importantly, system downtime will be greatly reduced.

There are two primary ways in which heat is removed from a hydraulic system: natural convection and forced convection. Another form of heat transmission, radiation, may also occur. However, the effect of heat radiation tends to be small. Natural convection occurs as heat moves from system components to the atmosphere. This will occur due to the laws of thermodynamics. Heat will naturally flow from a hotter region to a cooler one, and the rate of heat transfer is determined by the temperature difference. In other words, the greater the temperature difference (gradient), the more heat is transferred or removed in a given time frame. Smaller systems with lower operating temperatures may be able to rely solely on this natural convection. However, whenever natural convection does not provide sufficient cooling, a heat exchanger must be installed. A heat exchanger uses forced convection to remove heat.

Choosing the right heat exchanger for a particular hydraulic system is a complex exercise. There are many factors to consider and a wide range of heat exchanger types. The choice of a heat exchanger is generally determined by the type of system to be cooled. Several parameters must be taken into consideration. Fortunately, most heat exchanger manufacturers offer software and other resources to help determine the best fit for a particular application. When working with a manufacturer, the following information will need to be provided:

- Oil heat load in BTU/Hr.

- Oil flow in GPM

- Maximum required oil temperature

- Maximum ambient air temperature during system operation

- Environmental contaminants that may affect the system

- Maximum allowable pressure drop across the heat exchanger

- The inlet water temperature and flow (water-cooled heat exchanger)

Once these parameters have been defined, the next steps in the process include what type heat exchanger to use. The choices are air-cooled heat exchangers and various types of water-cooled heat exchangers.

Air-Cooled Heat Exchanger

When no water source is available, the choice is normally limited to this type of heat exchanger. As the name implies, air-cooled heat exchangers use the surrounding air to receive heat. The oil is ported to tubes which are bonded to fins. A fan is used to produce air flow through the fins, and the heat in the oil is transferred to the air. One major drawback to this type of heat exchanger is that it becomes less efficient as the ambient air temperature rises. As the ambient air temperature rises, its ability to absorb heat (thermal resistance) also rises. This is due to the laws of thermodynamics mentioned previously. Increasing the air flow through the heat exchanger helps to decrease this thermal resistance, but the air is not as good a heat conductor as water and other cooling liquids.

Air-Cooled Heat Exchanger

Water-Cooled Heat Exchangers

These heat exchangers are usually more efficient, as water is a much better heat conductor. In addition, the water can be chilled to reduce the thermal resistance which leads to even greater efficiency. However, using pure water can lead to mineral deposits inside the tubes which will inhibit heat transfer, so this must be considered from a maintenance standpoint. These deposits can be greatly reduced by using a glycol or other type solution.

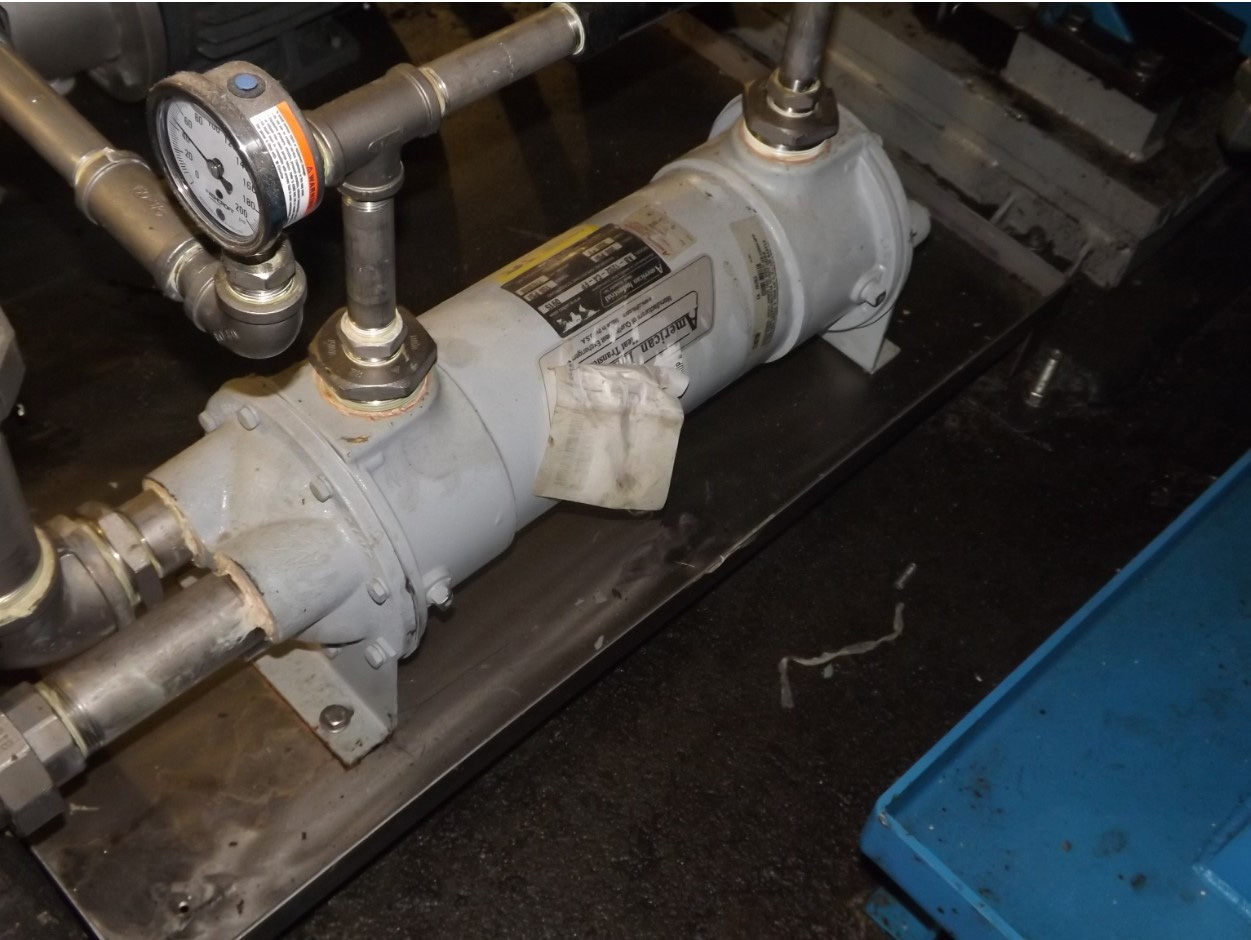

Shell and Tube Heat Exchanger

Where water or some other liquid is available for cooling, this type heat exchanger has been a mainstay for over 50 years. Oil is ported through the heat exchanger shell. Water is ported through tubes which run the length of the shell and heat in the oil is transferred to the water.

Shell and Tube Heat Exchanger

Brazed Plate Heat Exchanger / Gasketed Plate Heat Exchanger

Plate Type Heat Exchanger

With this type heat exchanger, heat is transferred by way of a series of stainless steel plates. The heat exchanger may be of either “brazed” or “gasketed” construction. The number of plates varies according to the desired heat transfer capacity. The oil is ported through alternating plates and water (or other cooling liquid) is ported through alternating plates. Once again, heat is transferred from the oil to the water.

Spiral Heat Exchanger

This type heat exchanger is of a relatively new design. It is manufactured by rolling two long steel plates around a center core. This forms two concentric spiral flow passages, one for the oil and one for the water. The plate edges are welded shut to prevent intermixing of the oil and water. This type heat exchanger offers excellent thermal efficiency.

Spiral Heat Exchanger

Once the size and type of heat exchanger has been determined, the proper location of the heat exchanger must be determined. Unfortunately, many designers consider the heat exchanger an “accessory”. As a result, the location of the heat exchanger is often an afterthought. However, we have shown that the heat exchanger it is an integral part of any hydraulic system and consideration should be made as to location. Since heat exchangers are low pressure devices, they are typically located in one of three locations:

Pump case drain line

A low-pressure bypass check valve should be used to prevent pump shaft seal damage in the event the heat exchanger becomes plugged with contaminants.

System Return Line

A bypass check valve should be used to prevent damage in the event the heat exchanger becomes plugged with contaminants.

Separate filtering and cooling circuit

A cooling circuit relief valve or bypass check valve should be used to prevent damage in the event the heat exchanger becomes plugged with contaminants.

In the case of an air-cooled unit, it should be located in an area with as low an ambient air temperature as possible. This will provide for maximum heat transfer. Ease of future servicing of any heat exchanger should also be taken into consideration. Selection of the right heat exchanger for the application as well as location and maintenance will help ensure trouble-free hydraulic system operation.